In order to recharge the batteries and continue to offer the best service to our customers we will close from August 17 to 30, both including

In order to recharge the batteries and continue to offer the best service to our customers we will close from August 17 to 30, both including

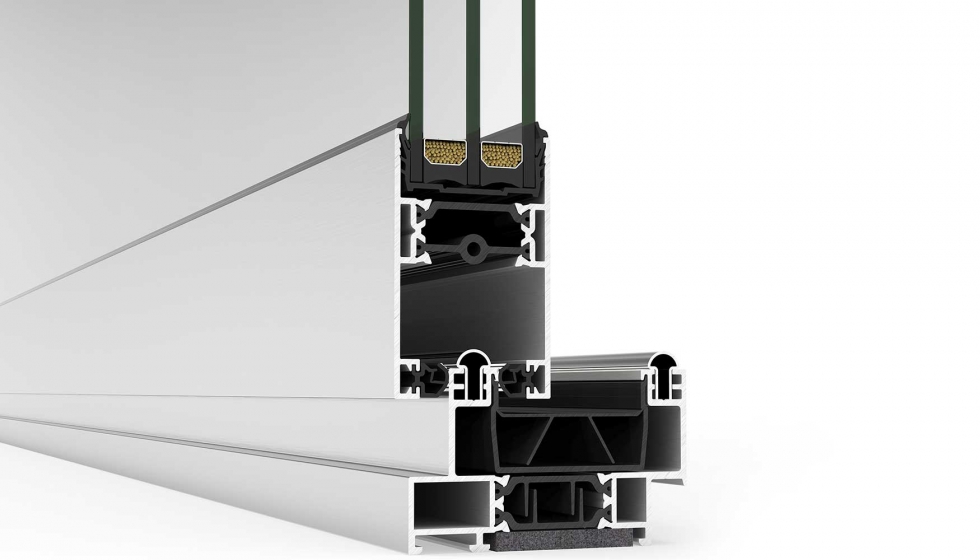

CORTIZO bets on enclosure systems that combine high thermal and acoustic performance with state-of-the-art designs, factors that star in the demands of the market and its innovation strategy. For this reason, the R&D&I department of the Galician multinational continues to develop new accessories for the most demanded series with the aim of improving its manufacturing, installation and handling, but without altering the aesthetic harmony of the whole.

The Galician multinational expands its range of accessories with a closure integrated in the central knot for the COR VISION PLUS slide and with the hidden drainage system for the COR 70 Industrial series, COR 70 Hidden Sheet and COR 70 Hidden Blade C16 ST

Following this line, the padd aftermarket has just launched a hidden handle for the manual opening of the COR Vision Plus system. The new solution integrates the closure into the central knot, making it imperceptible in the front view and allowing to completely hide the lateral encounter of the inner sheet, as in the motorized version. It is a hidden closure that can be lacquered in any color, thus giving greater uniformity to the whole. With this solution, the minimalist line of this premium slide is reinforced, which also incorporated in the last year the option to fully fill the lower profile and integrate it with the finish of the floor (pavement, floor, ceramic…), thus achieving a transition without any obstacle between the interior and exterior of the house.

On the other hand, CORTIZO has also expanded the range of accessories for its hinged windows, developing a new hidden drainage system for the COR 70 Industrial, COR 70 Hidden Blade and COR 70 Hidden Blade C16 ST series. This solution is based on the incorporation of a new gasket at the bottom of the frame to evacuate the water, replacing the usual drainage caps placed on the front. This results in a totally clean exterior aesthetic, without any complement in the frame, at the same time that the installation of the window is facilitated, allowing to place the base of the frame on the work itself. These hinged systems also feature hardware and accessory options that minimize the visual impact on the inner side of the window. Among them, highlights the new hidden hinges of 180o, which allow the total opening of the leaves, or the new handles: Arch Invisible, imperceptible in the front view and designed for the COR 70 Hidden Sheet of European channel, and Minimalist, valid for all series hinged and based on a careful design in which the shield is dispensed to enhance the avant-garde aesthetics of these carpentry.

Several provinces and municipalities have progressed in the de-escalaada process, moving to phase 1. One aspect in which, throughout the health crisis, the focus has been on the shortening of the cycle of virus contagion, has been at the time of its survival on different surfaces. Something we will have to continue to pay attention to in the successive phases of de-escalation to avoid possible upturns and aggravation of the improvement situation that we are gradually achieving.

To this end, the Ministry of Health presented through a scientific-technical report the survivability that the Covid-19 has in different materials, something to which factors such as humidity, temperature and, of course, the material itself will affect. Based on his own research on the persistence of other coronaviruses on inanimate surfaces outside an organism, from The Journal Of Hospital Infection estimates that the Covid-19 would survive 2 to 8 hours on aluminum, compared to the 2 days it would on steel, the 4 days it would do in wood and glass, or 5 days in metal and ceramics. Finally, plastic would be the surface between those analyzed (all of them daily surfaces and present in our environment) where the longest would survive: more than 5 days.

Outside of a human organism, it is estimated that the Covid-19 would survive between 2 and 8 hours on aluminum, compared to the several days it would on other materials such as plastic.

With this data in hand, from the AEA – the Spanish Aluminum Association, which represents more than 600 companies in the sector – we want to claim the importance of aluminum as a material in areas such as sanitary, where measures for the containment of the virus must be as demanding and effective as possible.

Centers that have been decisive during the current pandemic situation, such as the three field hospitals set up in Valencia (next to La Fe de Valencia and the two Generals of Alicante and Castellón), had aluminum as a fundamental structural material. A decision that was not at all casual; if these field hospitals were to receive hundreds of infected patients, it was necessary that the predominant and present materials were those in which the virus had a shorter survival period.

The Ministry of Health, Ana Barceló, speaking of the safety of these three enclosures, pointed out precisely that they had been mounted with materials such as aluminum – instead of steel or iron – because the coronavirus would not survive more than two hours on these surfaces.

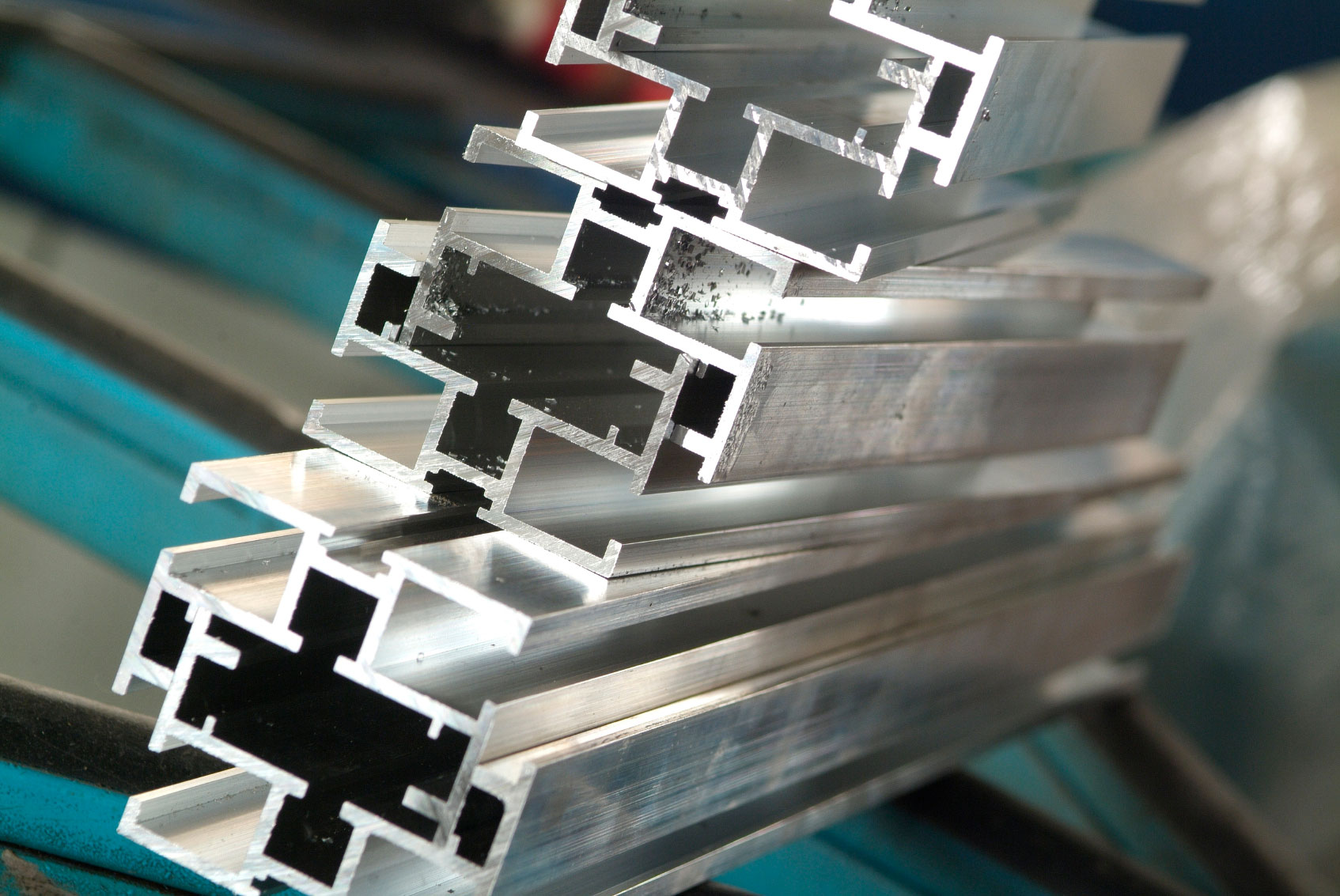

And not only that; In addition, they needed to be built quickly, while it was necessary to ensure the stability of the structure. Under all these premises, aluminum was shown to be the ideal material for these purposes. Jon de Olabarria, Secretary-General of the AEA says “One of the sectors in which aluminum stands out is undoubtedly that of temporary structures. All this thanks to its ease of assembly and its lightness for transport and placement. Despite its low weight, it is a solid, hard and resistant material, which gives stability and safety to the structures. If we add to this that this is one of the surfaces on which the Covid-19 least resists, we are faced with a material that must prevail in areas such as sanitary.”

The Spanish Aluminum Association claims aluminium as one of the preferred materials for sectors such as health while the pandemic situation lasts.

In short, says Jon of Olabarria, “Among the materials that are most present in our daily lives and in the objects that surround us and that pass constantly through our hands, aluminum has been shown to be one of the least favors the permanence of the virus in it, which should place it as a prevalent material in the future or, at least, until a vaccine against Covid-19 is found. It is clear that we must maintain a strictness and consistency in the work of cleaning and disinfection more intense than ever. But on top of that, it will always help that those elements around us are surfaces or objects that we know safe after a couple of hours.”

On top of that, the AEA emphasizes that aluminum is a total and infinitely recyclable material without its qualities being diminished in successive recycling processes. Also, for the recycling process it requires only 5 of the energy that was needed to produce primary aluminium. However, any element that is created and used in the context of this pandemic and then discarded can be recycled and have successive and infinite lives.

Cortizo launches the new 4900 Corredera system, a standard sliding window with excellent thermal and acoustic features, characterized by a straight and avant-garde aesthetic with a reduced central knot of only 35 mm that allows to maximize the glazed surface of the window, thus favoring the entrance of light inside the rooms.

The 4900 Sliding system allows combinations of up to 6 sheets, with maximum dimensions each of 2200 mm wide and 2600 mm high, and weights of 240 kg.

The new Cortizo slider was born as an evolution of the 4200, one of the most demanded by its customers in recent years, and stands out for its great thermal insulation (Uw from 1.2 W / m²K) and acoustic (Rw up to 40 dB ), characteristics that come favored by its great capacity of glazing of up to 36 mm, which allows the installation of triple glasses, as well as by the break of thermal bridge with polyamide rods of 34 mm.

The multinational Alcoa announced on Wednesday to its European committee the decision to close two plants in Spain, those of Avilés and A Coruña, which employ, respectively, 317 and 369 workers. The company, which has explained to the workers the start of a “collective dismissal procedure” appealing to the high price of energy and alumina, the raw material, which have caused losses in both factories, keeps its production in the plant of San Cibrao (Lugo), which produces both aluminum and alumina. Although unexpected, the announcement has not surprised the workers: their union representatives maintain that the multinational has been letting both plants die without hardly investing in them, which has caused a “progressive loss of competitiveness.”

The company committees maintain that the closure has been flying over these two Alcoa plants in Spain for four years: since the multinational has to go to an annual auction in competition with other large intensive industries to get bonuses in its electricity tariff.

At the end of 2014, the company presented an ERE of extinction for the 800 workers who then added the factories of A Coruña and Avilés after having obtained less economic incentives than expected to meet the expenses in the interruptibility auction. The ordago worked: the Government organized another bid that satisfied Alcoa and this withdrew the ERE. Two years later, Alcoa threatened to sell both factories. The announcement, also frustrated, coincided again with the imminent energy auction.

Last June, the president of the multinational company, Roy Harvey, visited the Asturian plant and warned that changes were needed in the high prices of electricity that you have then only increased. The increase in the price of raw materials and energy has a serious impact on the company that already announced losses for this year and foresees a similar situation for the next one.

The workers say that the company has subjected the plants of Aviles and A Coruña to a progressive abandonment. Just five months ago, the chairman of the works council of A Coruña, Juan Carlos López Corbacho -representative of the 369 employees who remained after the dismissal of a hundred coinciding with the first interlude auction held in 2014- noted the progressive loss of competitiveness of the factory.

Corbacho publicly warned that electricity accounted for 40% of the production costs for the multinational and that the energy framework for the large industry in Spain did not offer security in the long term so the Spanish plants were weakening while the company was hiding in that context of uncertainty not to renew.

In the case of the Coruñesa plant, the deterioration was “palpable”, according to Corbacho, both in the facilities and in the competitiveness, for which the trade unionist claimed a “stable” energy model. Similarly, the company has been progressively reducing production at the Avilés factory as the price of electricity increases.

Now, the company adduces “productive and technological structural problems” of the two plants, among which it cites “its lower production capacity, less efficient technology and high fixed costs” and stresses that these structural problems, together with external market factors, such as China’s overcapacity of production, the high price of raw materials and the cost of energy, “have generated significant losses in these plants in the last two years. Losses that are expected to continue. ”

The situation in the Lugo factory, with 1,600 workers, is different. The company “can deal with the poor results of the alumina plant with the benefits it obtains with aluminum, so there are no losses here,” says the union representative of the CIG on the works council, José Manuel Peña . The workers of the plant in Lugo have told the management their “total disagreement” with the closure of the other two factories.

Both the Xunta de Galicia and the Principality of Asturias have rejected the decision and the Galician president, Alberto Núñez Feijóo, has blamed the Government for not having spent “the economic part reserved in the General Budgets of 2018 for electrointensive companies”. For his part, the Asturian president, Javier Fernández, has rejected “the unusual way of proceeding” of the company that, he assures, until now had not warned “by any means” of this possibility.

The Ministry of Industry, Commerce and Tourism has shown its surprise and concern over the announcement that, while maintaining, the company “had never reported that it could take a decision in this regard” in the meetings held in the last three months and has asked the company to start a process of

CORTIZO, the Spanish leader and European benchmark in the manufacture of aluminum and PVC profiles for architecture and industry, closed 2017 with record figures, once again setting record highs for turnover, production and employment.

Last year, the Galician multinational recorded a turnover of 554 million euros, which represents an increase of 17.9% compared to the 470 million of the previous year. These positive data are driven by a growth in production, which registered a new maximum, reaching 75 824 tons of aluminum profiles (+ 6.7%) and 958 000 PVC bars (+ 68%). The percentage of sales abroad was 70.7% with sales to 60 different countries; Germany, France and the United Kingdom repeat as their main markets. “We have been growing for five consecutive years, but our satisfaction is not only because we sell more and more, but also because we also sell products with greater added value adapted to markets as demanding as Central European or Scandinavian,” says Antonio B. Picón, director of the Industrial division of CORTIZO.

The increase in sales and production has had an impact on the creation of 290 new jobs in the CORTIZO group, increasing its workforce to 2,800 employees. This growth has been especially significant in its production centers in Padrón, where it has 1539 employees, 160 more than in the previous year. Throughout Spain, the Galician multinational currently employs 2112 people.

Investment of 48.5 million

Within the Strategic Plan 2017 – 2020, aimed at increasing the productive capacity of its factories and improving its logistics network, CORTIZO invested 48.5 million last year. In Padrón, it allocated 19.6 million to the start-up of a new extrusion press of 2500 tons of power, a new lacquering plant, another one of chemical shine and new extrusion lines in the productive center of PVC. In Poland, CORTIZO has doubled its factory, which has been equipped with a new extrusion press, an anodizing plant and a machining center, which meant an outlay of 14.3 million. In France, the works are moving at a great pace and next summer will have a new extrusion press and a new intelligent warehouse of aluminum profiles in its production center in Chemillé. For that project, it has already allocated 8.2 million in 2017, approximately half of the total of the operation.

In terms of improving its logistics network, CORTIZO has invested 6.4 million in the expansion of its offices in Zaragoza, Zamora and Álava, and in the start-up of a new warehouse of aluminum and PVC systems for architecture in its factory in Tenerife.